There’s never a wrong time to perfect your metalworking skills. All you have to do is follow a few practices. Read these awesome tips for becoming a better metal fabricator today!

Switch Up Your Techniques

When you master certain techniques, it’s best to get creative and try new things. Attempt a new project only using new techniques. Though you may have a rocky start, challenging yourself lets you step out of your comfort zone. If you need inspiration, follow skilled fabricators on social media and see the type of projects they complete.

Be Mindful of Your Equipment

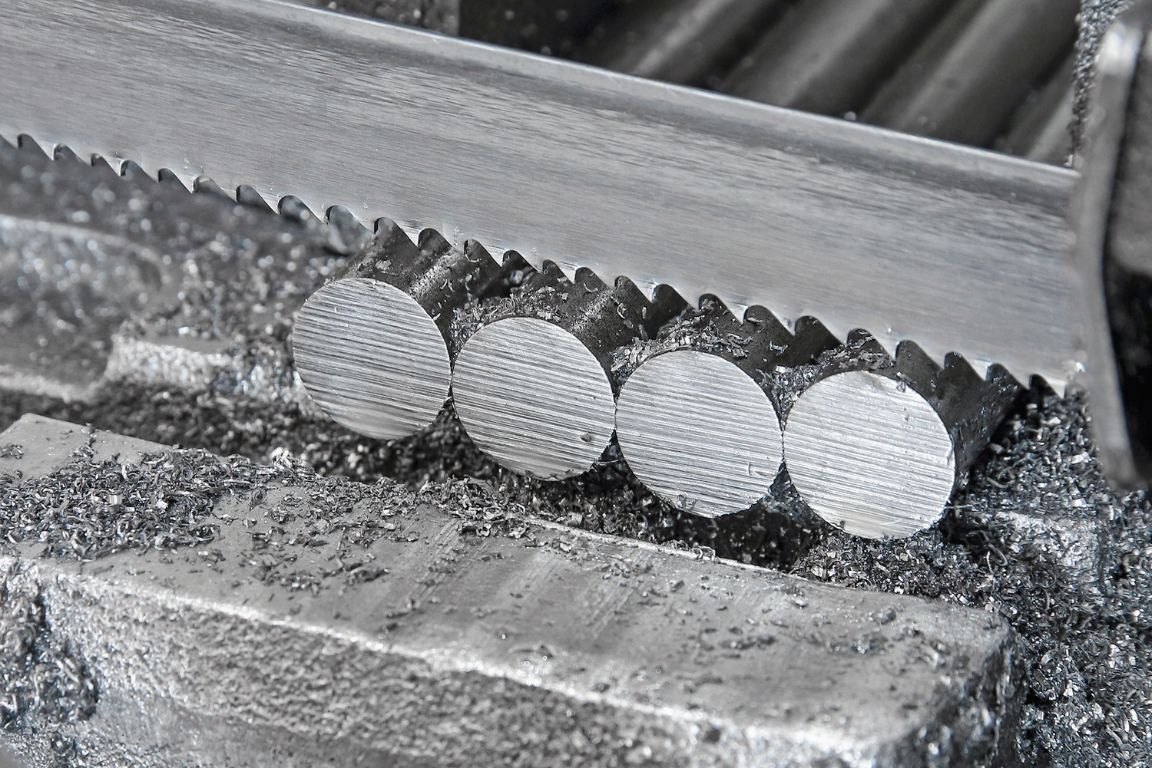

Precision and accuracy are essential components of metalworking. To maintain accurate results, you must pay attention to your equipment. Simple practices like using the right lubricants and replacing hydraulic fluids are essential to the functionality of your machines and tools.

It’s also important to ensure that you set the machines to the right setting for metal cutting. You can follow a guide to setting band saw blade tension to ensure that your blades produce accurate cuts.

Consider Seeking a Certification

You already have the skills; why not get a certification for your resume? The American Welding Society, The Fabricator and Manufacturers Association, and The Society of Manufacturing Engineers offer accreditation and certifications to fabricators. Use the certifications to apply for jobs, perfect your skills, or meet other people in the industry. You won’t regret seeking accreditations and may create new connections.

Always Maintain a Clean Workspace

Another tip for becoming a better metal fabricator is always maintaining a clean workspace. Of course, as an experienced fabricator, you understand the importance of cleanliness. However, a quick refresher is always helpful! Wiping away excess grease, oil, and dust is essential because impurities can absorb in the metal. This will create issues in your project and affect precision cutting. Wiping down your band saw and other machines maintains equipment. Ultimately, tidying up your workspace helps metalworking projects.

Never Forget About Safety

When you become an expert at something, it’s easy to find shortcuts or become lax on safety protocols. However, metal fabricating is a skill where you must prioritize safety for your well-being. Wearing safety goggles and closed-toe shoes and tying back your hair is critical. Don’t let your guard down because mishaps can happen at any time. Stay safe and follow the best practices.

There’s never a wrong time to perfect your metalworking skills. All you have to do is follow a few practices. Read these awesome tips for becoming a better metal fabricator today!

Switch Up Your Techniques

When you master certain techniques, it’s best to get creative and try new things. Attempt a new project only using new techniques. Though you may have a rocky start, challenging yourself lets you step out of your comfort zone. If you need inspiration, follow skilled fabricators on social media and see the type of projects they complete.

Be Mindful of Your Equipment

Precision and accuracy are essential components of metalworking. To maintain accurate results, you must pay attention to your equipment. Simple practices like using the right lubricants and replacing hydraulic fluids are essential to the functionality of your machines and tools.

It’s also important to ensure that you set the machines to the right setting for metal cutting. You can follow a guide to setting band saw blade tension to ensure that your blades produce accurate cuts.

Consider Seeking a Certification

You already have the skills; why not get a certification for your resume? The American Welding Society, The Fabricator and Manufacturers Association, and The Society of Manufacturing Engineers offer accreditation and certifications to fabricators. Use the certifications to apply for jobs, perfect your skills, or meet other people in the industry. You won’t regret seeking accreditations and may create new connections.

Always Maintain a Clean Workspace

Another tip for becoming a better metal fabricator is always maintaining a clean workspace. Of course, as an experienced fabricator, you understand the importance of cleanliness. However, a quick refresher is always helpful! Wiping away excess grease, oil, and dust is essential because impurities can absorb in the metal. This will create issues in your project and affect precision cutting. Wiping down your band saw and other machines maintains equipment. Ultimately, tidying up your workspace helps metalworking projects.

Never Forget About Safety

When you become an expert at something, it’s easy to find shortcuts or become lax on safety protocols. However, metal fabricating is a skill where you must prioritize safety for your well-being. Wearing safety goggles and closed-toe shoes and tying back your hair is critical. Don’t let your guard down because mishaps can happen at any time. Stay safe and follow the best practices.