In 2022, the global market for computer numerical control (CNC) machining services is expected to reach $186.16 billion. This growth is attributed to the advantages that CNC machining has over traditional machining methods. These advantages include increased accuracy, consistent quality, and higher productivity.

Different CNC machining services are available depending on the customer’s specific needs. If you’re looking for a custom machining shop to create parts for your business, you’ll need to decide which type of CNC machining service is best for your needs. In this blog post, you’ll learn about the different types of CNC machining services and how to choose the right one for your business.

What is CNC Machining?

It is a manufacturing process that uses computer-controlled machine tools to remove material from a workpiece. The process can be used to create parts of various shapes and sizes. It is often used for custom or prototype manufacturing, as well as for mass production.

It is estimated that over 80% of all manufactured products today are made using CNC machining. This manufacturing process is prevalent because it offers several advantages over traditional machining methods. Additionally, it can be used to create parts with very intricate designs.

Different Types of CNC Machining Services

Different CNC machining services are available depending on the customer’s specific needs.

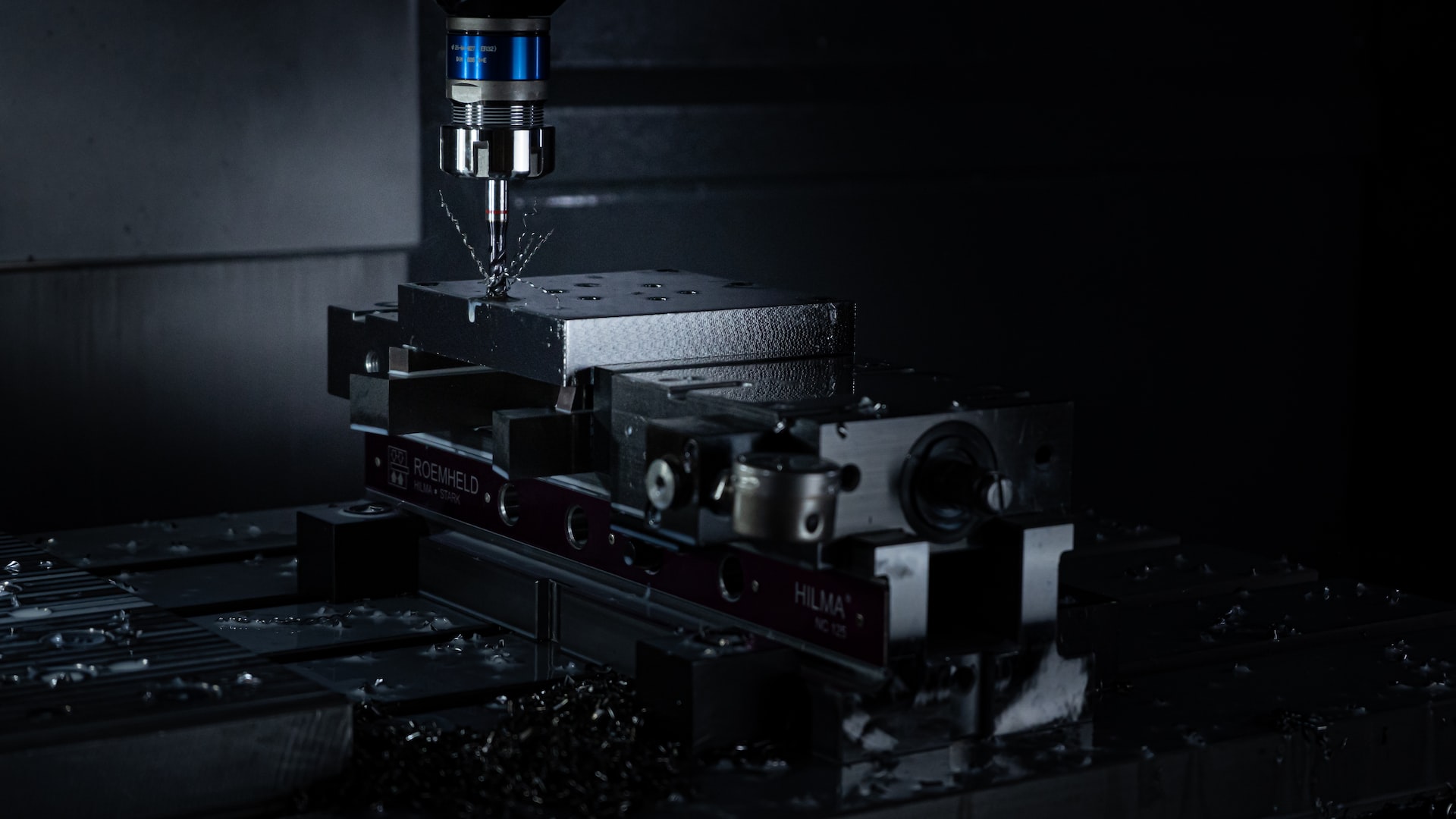

CNC Milling

It is a process that uses computerized controls to remove material from a workpiece. The milling machine consists of a cutting tool, typically a rotating end mill, and a table that moves the workpiece in the X, Y, and Z axes. In CNC milling, the computer controls the position of the cutting tool, speed, and depth of the cut.

The operator programs the machine with instructions, which tell it how to move the cutting tool and what size end mill to use. CNC milling can be used to produce parts with complex shapes, and it can be used to create slots, pockets, and other machined features. It is an efficient way to make high-precision parts with complex shapes. It can also produce large quantities of parts quickly and with little operator intervention.

CNC Turning

CNC turning is a process that uses computer-controlled lathes to create precise cylindrical parts. The process begins by creating a 3D model of the desired part. This model is then used to generate a CNC code, which tells the lathe what kind of cuts to make and in what order.

Once the code is generated, it is fed into the lathe, which cuts the material according to specified instructions. The finished product can then be removed from the lathe and sanded or polished. It is an efficient and accurate way to create parts for various applications.

About 60% of all CNC machining services perform using a lathe. This is because lathes are very versatile and can create various parts. In addition, lathes are relatively simple to operate and require less training than other CNC machines.

CNC turning services may be the best option if you need a cylindrical custom part. This type of machining is accurate, efficient, and can perform on a variety of materials.

Ending Thought

If you’re looking for a custom machining shop to create parts for your business, you’ll need to decide which type of CNC machining service is best for your needs. Many well-known companies offer custom CNC machining services, so do your research before selecting a provider. They will be able to help you determine which type of machine is best suited for your application and produce the parts you need.

When choosing a custom machining shop, it’s essential to consider the specific needs of your business. You’ll also want to compare the prices and services of different shops to find the one that best suits your needs.