Efficiency and productivity are two of the most important factors for any business, but they’re non-negotiable in the manufacturing industry. In order for your manufacturing company to make a profit, you must finish products on time. If you’d like to learn how to make your manufacturing facility more efficient, we’ve got you covered. Read our guide below.

Have consistent training

Your workers are the backbone of your company and, regardless of if your workers are veterans in the industry, they could use a refresher from time to time. Unless every worker is up to speed and on the same page, you will have inefficiencies and people may make preventable mistakes. As the facility owner or manager, it’s your duty to ensure everyone receives proper training on procedures and machinery.

Analyze your workflow

You should regularly inspect the processes and workflow that you have in place. Even if something is a daily operation, a lot of the time, there’s a way to make the process better. While analyzing the workflow, you should collect data such as how long it takes to produce one final product. Additionally, you’ll want to see where that time can be reduced; sometimes, the solution is as simple as reorganizing your floor plan and machines’ placements. If workers consistently have to backtrack and carry materials to the other side of the facility, that’s rather inefficient. Why not just have the materials next to the workstation to begin with? Sometimes, the solution is found in the people. Everyone has their own set of strengths and weaknesses. Take advantage of their strengths and help them improve on their weaknesses. Your organization is only as strong as your people, after all.

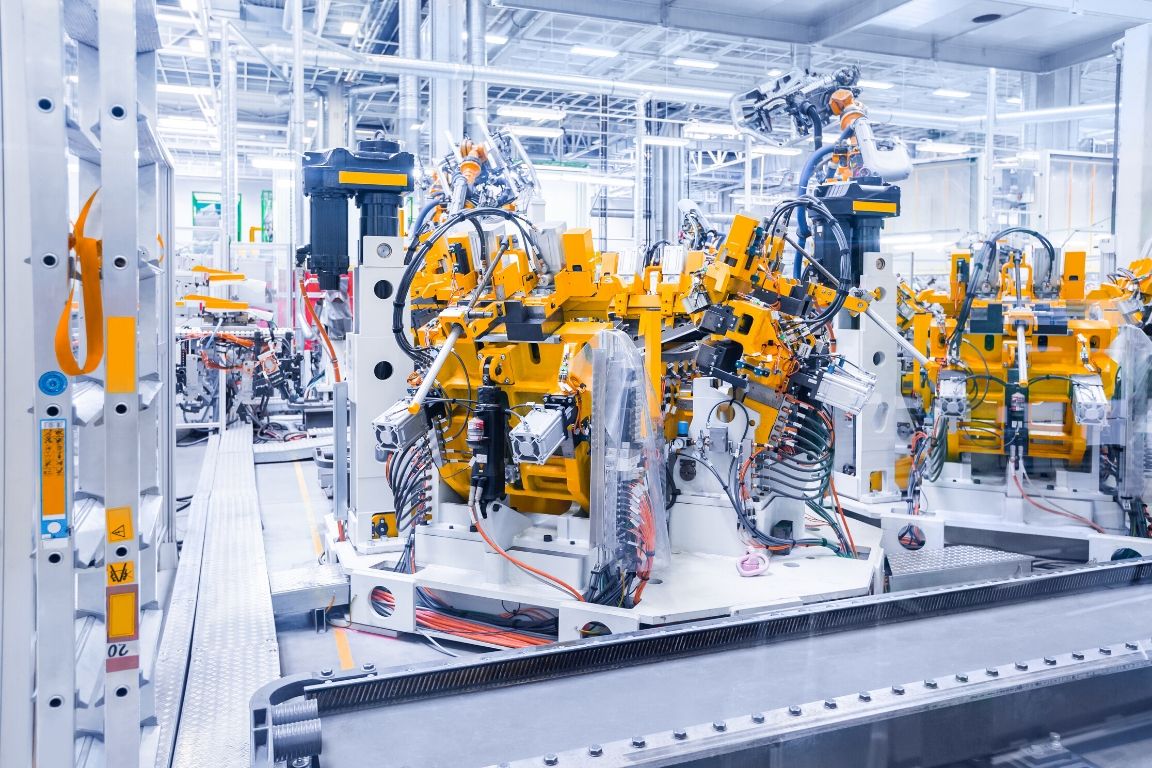

Lean into automation

Adopting modern technology is a path to making your manufacturing facility more efficient. You don’t even necessarily need brand-new technology—you merely need to update parts of your existing machinery. A lot of manufacturing facilities make the mistake of not maintaining a machine’s motor, which only costs you more in the long run. That said, sometimes motors are beyond maintenance and repair and you just need a replacement. Make sure you know what to consider when choosing an electric motor before shopping around.

Every manufacturing facility can improve in some capacity and, usually, that room for improvement is somewhere in the efficiency department. As the leader of the facility, it’s your responsibility to put new procedures, people, or machinery in place to improve your overall efficiency and profitability.