What is PDM?

Product data management or Product information management is the business function often within product lifecycle management that is responsible for the management and publication of product data. In software engineering, this is known as version control.

What is PLM?

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal of manufactured products.

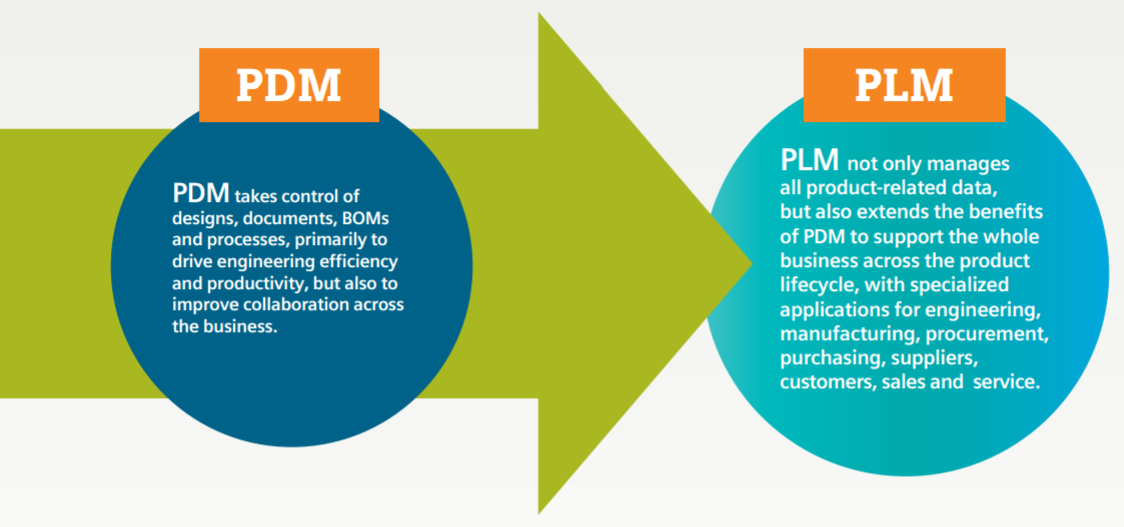

PDM vs PLM

The differences between PDM and PLM are considerable. PDM is the specific type of product within PLM. PDM focuses on managing product data throughout the product’s entire life. The focus is on managing the data and not on controlling the data. Managing without controlling is about understanding that you do not necessarily know what is required and gaining insight through investigation. An analogy would be that butler service is about serving the food once you know what the customer wants to eat, whereas a chef is about cooking what you want to eat. Within PDM, data control is often provided through version control or data deduplication. Data control means it is not necessarily possible to change any of the data.

The purpose of PLM is to support the design, engineering, manufacturing, and service of a product. PLM becomes more effective when all the participants in the value chain are involved. Data is central in PLM, and the goal is to capture data in a manner that can be used to control necessary processes.

Through the use of PLM, the product lifecycle is managed throughout all stages: design, development, manufacture, delivery, distribution, service, and disposal. The PDM versions are more likely to be part of this lifecycle in a material form while PLM versions are more likely to be conceptual versions.

PDM and PLM have a close relationship to one another. The PDM works to the data center, the operational PDM, and ultimately the PLM for data integrity. There is a close relationship with the PDM and the requirements manager as they look after the data in support of decisions on what is needed to augment the design.

Existing product lifecycle management systems are deployed in several industries. These systems supply various benefits, such as the following:

• Comprehensive general knowledge about an entire product or product line, such as information about that product’s design, testing, location, status, and more;

• The ability to coordinate various activities related to product development while preventing many types of mistakes;

• Better visibility into the process;

• And better product understanding and better ability to quickly respond to a changing market.

The use of a PLM solution ensures the quality of products from their conception to their end of life.

A product lifecycle management system is used throughout the product lifecycle. The different stages include:

• market analysis, where a company determines whether to create or change a product, and how to do so;

• requirements management, where a company must determine what the customer wants and needs;

• design phase, where the idea is created and the product is designed to meet the customer’s requirements;

• prototype manufacture, where initial manufacturing is carried out in order to verify the product design;

• mass production, where mass-produced products are manufactured in the required quantities;

• marketing, where sales of the product take place;

• support, where a company continues to support the product for a certain guaranteed period; and

• disposal or end of service, where the product must be disposed of and all associated data must be deleted or archived.

Other names for product lifecycle management include product-oriented business processes, product data management (EDM/PDM), and product lifecycle management (PLM/PLMII).

Product lifecycle management is used by many large companies. More than a third of the Fortune 500 companies use PLM systems, and this is predicted to increase to more than 50% by 2010.

In PLM, the product metadata is a central focus. The metadata describes what the expected product is to be used for. The data also contains the cost for obtaining, producing, and using the product. The data must be accurate and detailed. Metadata allows the user to use a standard terminology, and it also ensures that the right product is being designed, developed, or delivered.

Product data management is similar to technical data management. Technical data management typically uses software suites that perform automatic data entry, document digitization, and conversion to a standard format. Product data management is also similar to business data management and is used for operational purposes in an enterprise and is generally stored in a central business data warehouse for easy access. The business data warehouse works best when there is a single reference source for all the data. Product data entries and updates are performed in a time-based (e.g., when a change is made or the product is updated) or event-based way.

Product data management also makes use of the concept of metadata. It manages the metadata of product data in order to ensure that different users refer to the product by the same accurate and detailed data.

Product data management may also integrate with other types of data management. For example, in the medical industry, product data management may be combined with medical data management to collect information about an individual’s medical history.

Product data management can be broken down into many phases. One way of doing this is to break them down to the following:

• Business Analyzes the lifecycle of the product, and the process to go through to design and implement the product.

• Data Updates and collection of data from a variety of sources from different teams. It is important that team members enter data in the same format in order to avoid confusion.

• Lifecycle Definition of the life cycle for a product.

• Phases Identification and customization of specific phases that may be unique to the specific product and company.

• Handling of the data throughout the lifecycle.

• Metadata Standards for casing and naming conventions that will ensure data integrity throughout the data lifecycle.

The above phases are considered key to a successful PDM solution. All the data that is needed for each phase must be present and in the correct format.

PLM

Production is creating a product or providing a service.

PLM and PDM are typically used in manufacturing.

PLM includes the following:

• Supply chain management

• Product lifecycle management

• Change Management

Production is supported by the following:

• Business systems/ERP

• Technical systems/PLM

• Manufacturing execution systems/automation

• Supply chain management systems

The overall goal of PLM is to improve the use of information, data, and technology to manage and transform production from good to excellence and to transform the enterprise as a whole through the success of the transformation of production.

There are a number of definitions of PLM.

• One is a continuous process that harnesses the organizational and industrial skills of people to facilitate the transformation of the product from its conception to its end-of-life. The desired outcome is a better match between customer demand and service, and the sustainable delivery of products and services that satisfy the needs of the environment.

• Another is an integrated technology and information management system that enables a seamless exchange of information throughout the product development cycle and supply chain.

• Yet another is a system that harnesses the organizational and industrial skills of the people to facilitate the transformation of the product, from its conception to its end-of-life. The end result is a better match between customer demand and service, and the sustainable delivery of products and services that satisfy the needs of the environment.

• Another is a coordinated approach to managing the product through its life.

• Yet another is a synchronization of technology and information management across the product delivery process. This involves creating a coherent and coordinated process that integrates all the functions of the enterprise responsible for delivering products and services.

There are different types of PLM systems; for example, there are enterprise PLM systems that are typically used in large companies, and there are customer PLM systems that are used for individual companies.

One potential way of looking at this is to break PLM systems into the following:

• end-user systems

• enterprise systems

End-user systems:

• Are used for communication between customers and producers of products.

• Are typically small, usually built on a customer-server architecture

• Are typically assembled by the user of the system and customised to the business

• Are locally installed and managed

Enterprise systems:

• Typically have more than one user, and typically offer more functionality than end-user systems

• Are usually built on a client-server architecture and are typically hosted by a central application service provider

• Are usually installed by toolkits and components that are supplied by the vendor

Application program interfaces (APIs) are typically used to access enterprise systems, research and development (R&D) systems, innovation systems, and supply chain systems.

End-user systems may use techniques such as web services to enable access to an enterprise system.

This is a typical lifecycle of any IT system.

The relationship between an enterprise system and end-user systems is shown below:

• The enterprise system allows companies to improve their product development processes and to gather vital information about their customers and their products.

• End-user systems, for example, a document management system, allow companies to deploy their product information to the shop floor, eliminating the miscommunication and delays that can affect supply chains.

The data must be structured and organized in a way that is understandable to people who are not data specialists. To do so, you will need workplace or organizational guidelines that govern the process for creating and changing product data. You may need the following models to ensure the collection of product data:

• Business rules and business processes model

• Products data dictionary

• Product taxonomy model

• User interface model

• Formats model

• Business rules model defines the policies and procedures the enterprise should execute to fulfill product management’s objectives.

• Products data dictionary details the description of the data that is used to define and update product information. The products data dictionary can be created in conjunction with other models.

• Product taxonomy model is used to map product information to other business information. The product taxonomy model defines the product structure and relationships. Data relationships can be used to refer to the product taxonomy model when performing data entry.

• The user interface model is used to define the standard interface for data entry through various channels. The user interface model can include different levels of detail.

• A format model includes the types of product information that need to be entered and the format of the data entered. An employee may create a complex format model that requires all information to be entered and to be entered in the same way; however, another person may create a simple format model.

When implementing a PLM system for a manufacturing company, consider the following:

• The number of enterprises using the system

• The size and number of products

• The number of locations where products are manufactured and sold

• The complexity of today’s products (versus transmission belts of the past, for example) and any regulatory issues

• The number of suppliers of parts for your products and the number of other companies that work with you to produce your products.

Implementing a PLM system can be difficult because of the number of steps required to get started. These steps are related to the following:

• Creating a project management office or project office to work on the implementation

• Identifying the stakeholders (the system must be beneficial to them)

• Defining the project stages and milestones

• Defining the products for the system

• Defining the system architecture

Cultural change is difficult to achieve; however, when this is done successfully it is a tremendous achievement 10 percent of the effort is in setting up the system, 30 percent is in deploying it, 30 percent is in training and 10 percent in culture change.

PLM systems can take a considerable amount of energy from the organization, which, in turn, needs to find creative ways to address this. One of the most common ways to address it is by using a PLM business analyst.

The British Standards Institute (BSI) published the Data Model eXtensible Business Reporting Language (XBRL) taxonomy, and defines it as a moment in the data modeling life cycle.

Much of the above can also be applied to other types of systems that support industrial processes.

• Integrated Product Design System (IPDS) is a cost effective, modular, comprehensive software solution, providing a single environment for design, engineering, manufacturing, quality, supply chain, project and facilities to manage the entire product life cycle.

• The IPDS Solution Suite, which comprises of 10 products, is a unified, industry-compliant solution designed to provide integrated and cost-effective product lifecycle management (PLM) software for companies of all sizes across a variety of industries.

• IPDS provides the following key capabilities:

- Product Definition:

• Efficiently define individual products and product families.

• Flexibly capture product design.

- Product Planning:

• Plan when and where to manufacture products.

• Collaboratively distribute the plan.

• Manage capacity.

- Configuration:

• Collect customer requirements, product requirements, and product design to manage the product configuration process.

• Standardize virtual prototypes.

- Supplier Involvement:

• Manage and optimize your product supply chain through collaboration with suppliers.

• Generate and manage quotes.

• Automate the order.

• Collaboratively manage purchase commitments.

- Automated Workflows with Visualization:

• Use the workflow editor for process automation.

• View the workflow with automated process mapping.

- Engineering:

• Coordinate the engineering effort.

• Understand the design structure.

• Optimize product design quality.

- Manufacturing:

• Manage the manufacturing process.

• Detect quality issues.

• Identify responsible actions.

• Traceability:

• Document the evidence of completed functional and physical processes.

• Track the progress and status of products.

- Quality:

• Plan, analyze, and manage quality management to achieve ISO standards.

• Manage non-conforming conditions to improve product quality with an easy-to-read line graph and tracking tool.

• Manage the artifact repository and maintain certification and standard files.

• Enter actions with barcode scanning.

• Track active and completed activities in the action log.

- Product Lifecycle Management:

• Prepare for eventual product disposal.

• Manage the product from cradle to grave.

- Product Data Management:

• Manage product data.

• Use the easy-to-use drag-and-drop grid.

• Generate custom objects.

• Apply automated quality control.

• Manage password-protected objects.

Each product component, for example, a drill bit, or a shoe, has information defining it. High level information such as what the components are, what they are made of and contact information. Reduced level information giving detail on the components name, colour and size.

This information is applied to the product lifecycle from its conception to its termination.

Product Lifecycle Management (PLM) is an information technology solution that the global manufacturing and industrial sectors are currently implementing to streamline the product development process.

Up to this point, this article has taken a look at the main reasons why PLM has become a hot topic with businesses in recent years and how it can be used to effectively manage product data.

Product Lifecycle Management can be divided into three main tasks, the first and most important of which is development. The second is manufacturing and the third is support.

This task focuses on developing the product. The product is designed, optimised and reduced using the various modelling techniques (CAE, for example).