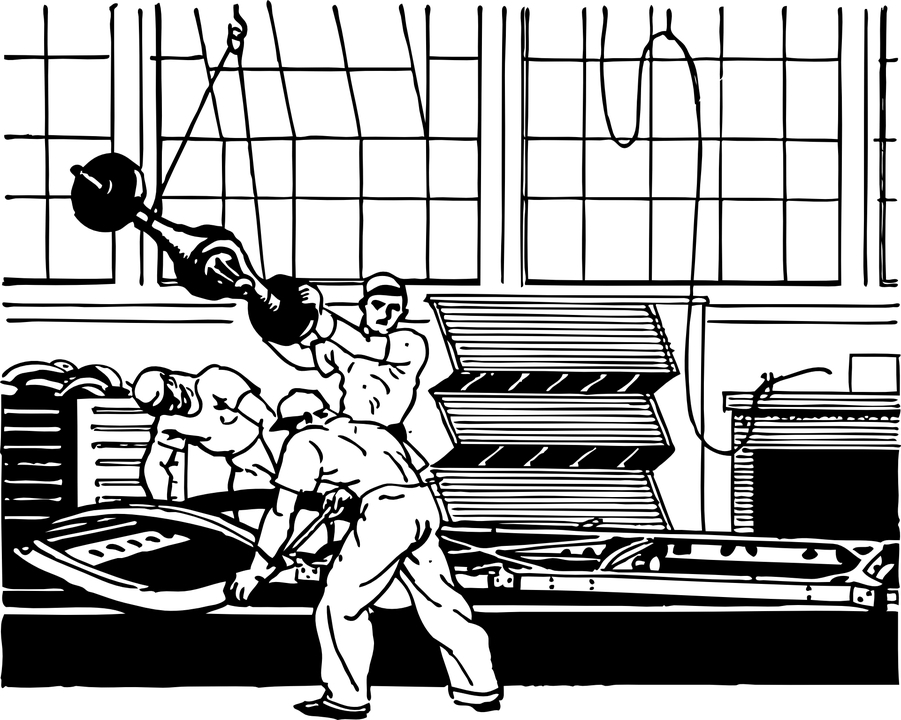

Starting a new production line can be daunting. There are so many things to consider – from the initial planning stages to ordering the necessary machinery and materials, to making sure everything is up and running smoothly.

Here are six tips that may come in handy during those early days.

Start With a Plan

Before you even begin to think about the specifics of your production line, create a comprehensive plan detailing all the steps you need to take from start to finish. Have this document accessible at every stage of the process so that everyone involved is on the same page and can reference it for updates.

For instance, your plan should list the equipment and materials you will need, the estimated costs associated with setting up your line, a timeline for production, and any other relevant details.

You can also make a proper business plan from this document to ensure the success of your production line. It should include a budget, a market analysis, and information about the products to be produced.

Contract Manufacturing and Fulfillment Partners

Contract manufacturing and fulfillment partners can help make the process of setting up a new production line much more efficient. In the words of the pros behind Advanced Manufacturing Solutions, you should look for suppliers and producers who have experience in the industry you’re working in and have access to the technology required for production. This will save you time, money, and energy as they will already be familiar with many of the processes involved.

Additionally, having a fulfillment partner will help with the shipping and distribution of your products and can provide you with cost-effective warehousing and transportation options that can improve your efficiency and reduce the time it takes to get products into the hands of customers.

Project Management Software

Project management software is essential for keeping track of all the tasks involved in setting up a new production line. It can help you keep track of costs, assign tasks to your team, and monitor progress in real-time so that you always know where things stand.

It can also provide a central platform for everyone involved in the process to store information and collaborate on projects. This will save time as everyone can access the same documents in the same place.

Of course, you can also use project management software to create detailed reports, track progress, and analyze performance data.

Proper Training

Once you have everything in place, it’s important to make sure that everyone is properly trained on the equipment and processes involved in the production line. This will ensure that your employees are knowledgeable about how things work and can troubleshoot any issues that may arise.

It’s also important to have a rigorous safety protocol in place and ensure that everyone is up-to-date on all safety regulations. This will help minimize the risk of accidents and injuries, as well as reduce the cost of insurance premiums.

Research Automation Technologies

If you haven’t already, consider researching automation technologies that can be incorporated into your production line. Automation technologies can help streamline production, reduce mistakes, and improve efficiency. Investing in the right technology can make a huge difference when it comes to creating a successful production line.

Research which automation tools are available and how they can benefit your business before investing in any specific products or services. For instance, you could invest in robots to help with the assembly and reduce the need for manual labor, or you could use analytics tools to help monitor and optimize the production process.

Marketing Strategies

Once your production line is up and running, you will need to develop a marketing strategy to make sure that your products are seen by the right people. Consider using both online and offline tactics such as paid advertising, search engine optimization (SEO) techniques, email campaigns, content creation, and social media outreach.

The key is to create an integrated strategy that will help your brand reach a broad audience and drive sales.

Continuous Improvement

The final step to creating a successful product line is to ensure that it’s always being improved upon. It’s important to keep up with industry trends, incorporate new technologies when they become available, and stay ahead of the competition.

Additionally, quality control processes should be implemented to make sure that your products are always meeting the highest standards. Regularly testing and updating your production line will ensure that you remain competitive and keep customers coming back for more

By following these steps, you can lay a solid foundation for a successful product line and maximize the efficiency of your operations. With the right combination of tools and strategies, you can create a reliable production line that will help your business grow and thrive.