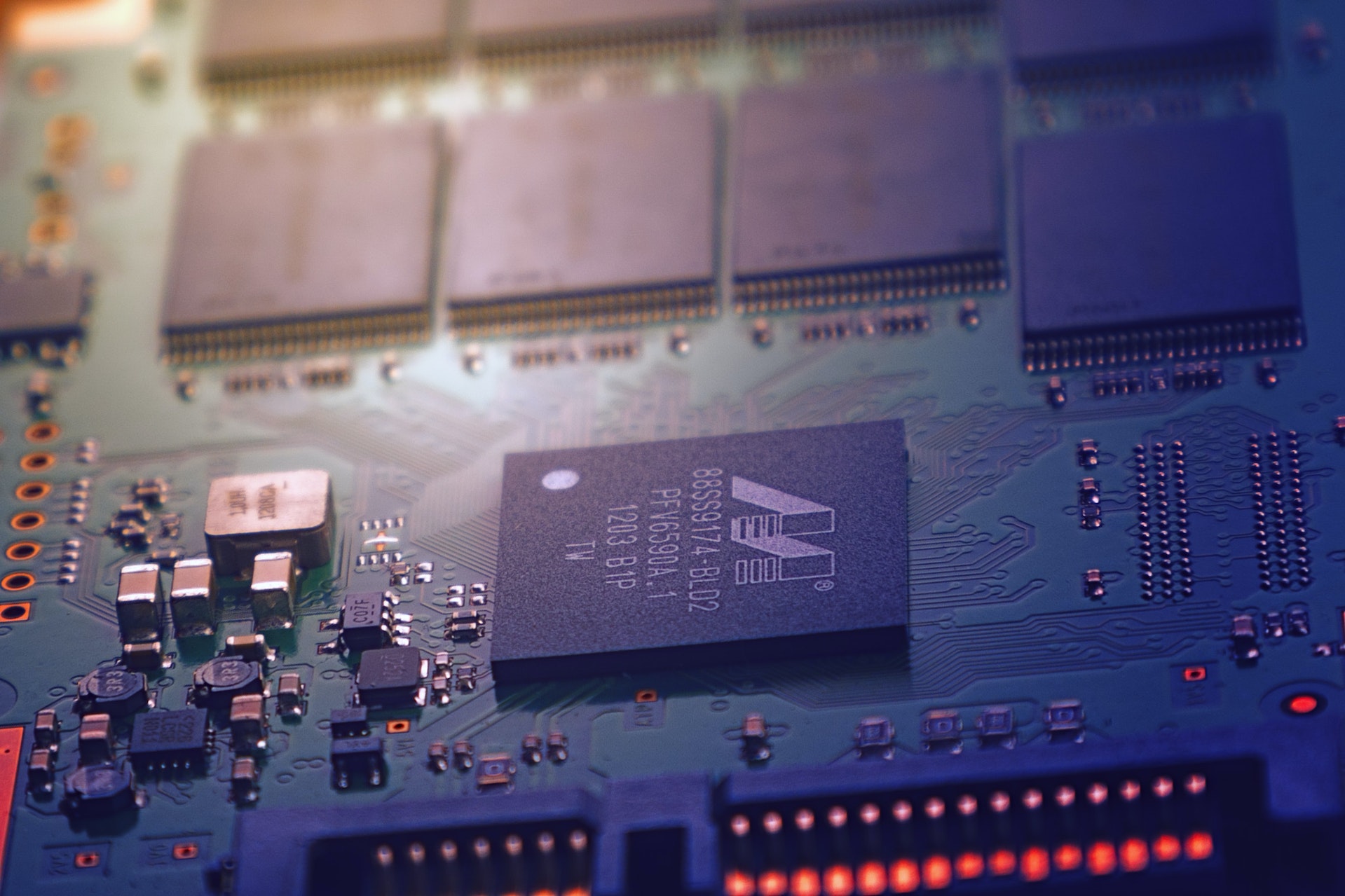

Just as most of us are aware and conscious of what others think of us and our activities, PCBAs or Printed Circuit Board Assemblies must also be conscious of their surroundings and impact on the nearby circuitry. PCBAs must fit in with their neighboring circuitry to ensure bigger, more complex electronic systems function smoothly. The EMI or Electromagnetic interference from a poorly designed PCB can cause disruptions in the circuitry comprising the overall functioning of the system, similar to how loud noises from our house can disturb our next-door neighbors. And just the same way, we seek to be good neighbors. Like the analogy, PCBAs should also be designed to be good neighbors.

EMI is the emitted radiation from any electronic device and its effects. EMC is a device’s ability to limit the levels of this unintentional EMI, especially if that harms other devices, and its ability to function normally when subjected to EMI. And EMC testing is a primary way to limit EMI. In this post, we will define and discuss what EMC testing is and why it is crucial to get it done.

What Is The Difference Between EMI and EMC?

Simply put, EMC is Electromagnetic compatibility and is best defined in terms of EMI. And a practical way to interpret EMI if it is limited to the range of 9 kHz and 275 GHz from the perspective of a communications system is as noise. This means that EMI is any unwanted signal that disrupts data transmission.

There are usually two sources of noise or EMI. Radiated EMI and conductive EMI. The former occurs through the air, and conductive EMI is directly transferred through another conductor. And EMC is the ability of nearby electronic systems to operate with very little interference from each other’s operation.

What Is EMC Testing?

EMC testing is basically the execution of testing protocols carried out at an EMI testing lab. It will check and analyze the levels of electromagnetic radiation from and to your board to determine its effect on the functionality and its possible impact on electronics in the immediate surroundings.

Why Is EMC Testing Important?

There are many reasons why PCBs should be tested for EMC. Some are:

Safety: This is the foremost reason for EMC testing. The basic motive behind testing them is to protect the safety of consumers and operators of the electronic equipment and systems on which the boards are used as a component.

Reliability: Apart from safety, reliability is the next factor that must be verified to see if the boards will perform as intended and satisfy their functional objectives based on where they are installed.

Standards and Regulations: Other than these two reasons, EMC testing is mandatory in most countries. Although from a regulatory perspective, only appropriate testing must be done to avoid non-compliance sanctions. This is usually decided by the location of the manufacturer, the end-user, or the industry for which the PCB is made.

Two Categories of Testing

EMC testing can be categorized into two groups:

Immunity Testing: This test measures how the electronic device will react when exposed to electromagnetic disturbances or noises. These tests are used to get clarity on the fact that the device will function as it is intended to in the operating environment.

Emissions Testing: This test measures the amount of electromagnetic noise an electronic device typically emits. These tests aim to ensure that any noise emitted from the device is well below the limits prescribed for that kind of device while assuring that it will not interfere with other devices operating in the same environment.

In a Nutshell

EMC testing is vital to ensure the electronic systems and PCBAs function properly. It helps address the issue of EMI between surrounding circuits which impacts the boards’ safety and reliability. This testing also ensures that the PCB conforms to the statutory regulations and standards.