In the intricate web of manufacturing and engineering, crimping machines play a pivotal role in creating secure, electrically conductive joints. If you’re in one of these industries, considering a crimping machine is necessary to ensure your products’ quality and reliability. We’ll explain the things you need to know about crimping machines, from how they work to their applications and maintenance.

How a Hydraulic Crimper Works

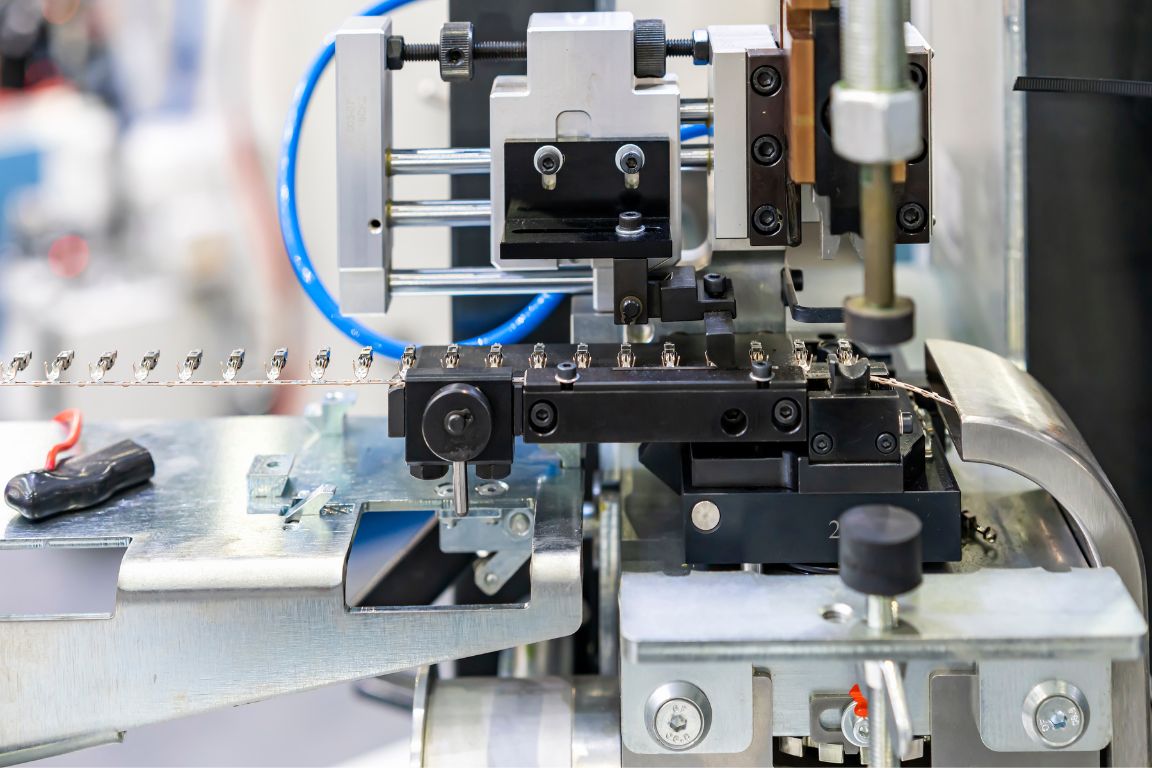

A hydraulic crimper utilizes hydraulic force to compress and deform materials, creating a tight and secure crimp. The process begins when the operator places the material, often a wire and a connector, into the crimper’s die.

Upon activation, the hydraulic system pumps fluid and generates pressure that drives the crimper’s piston forward. This action forces the die to close around the materials, exerting the necessary pressure to crimp them together. Once the crimping cycle is complete, the crimper releases the pressure, and the die opens, leaving behind a crimped connection ready for use.

More Than One Type of Crimping Machine

While hydraulic machines are common, there is more than one type of crimper. When choosing a crimping machine, you’ll have to consider the pros and cons of each system. Hydraulic crimping machines utilize hydraulic pressure to exert force on the crimp, making them ideal for use with thick wires.

Pneumatic crimping machines, on the other hand, rely on air pressure to function. Their speed and efficiency in repetitive tasks make them suitable for operations that need consistent results with medium force. Automatic crimping machines are useful for high-volume crimping jobs, ensuring precision, speed, and minimal manual intervention.

They’re Applicable to Many Industries and Applications

Another thing you need to know about crimping machines is their versatile utility. The following industries and manufacturing processes utilize crimpers:

Automotive: This industry often utilizes crimping machines for the wiring harnesses required for powertrains and infotainment systems.

Aerospace: Crimping ensures the wiring and terminals in aircraft are secure and reliable for thousands of flight hours.

Electronics: Crimping is essential for consistent and secure electrical connections for household appliances and sophisticated medical equipment.

Maintenance Is Crucial for Capability Over Time

Regularly maintaining crimping machines is crucial for ensuring optimal performance and extending operational life. These machines require periodic checks and adjustments to maintain accuracy and efficiency.

Neglecting maintenance can lead to decreased productivity, machine downtime, and the risk of compromised joint quality. This can result in electrical failures, which could have severe safety implications in industries like aerospace and automotive.

Conclusion

The world of crimping machines is vast and varied, much like the industries they serve. Whether you’re customizing a machine for your facility or looking for tips to maintain your current setup, understanding the ins and outs of crimping tools is vital for your success. If you’re in the market for one, consider these insights as a starting point to find the perfect machine for your needs.