PLM Software

The term product lifecycle management can be misleading, as PLM does not necessarily entail the management of the full product lifecycle. This may or may not encompass product support and retirement, legacy system management, or the development and deployment of new products. Further, an integrated, end-to-end, model-based approach to product lifecycle management is not necessarily developed by the tools of PLM, but rather realized through the application of PLM systems and techniques to support the optimization of the whole lifecycle, including the full breadth of product behaviors.

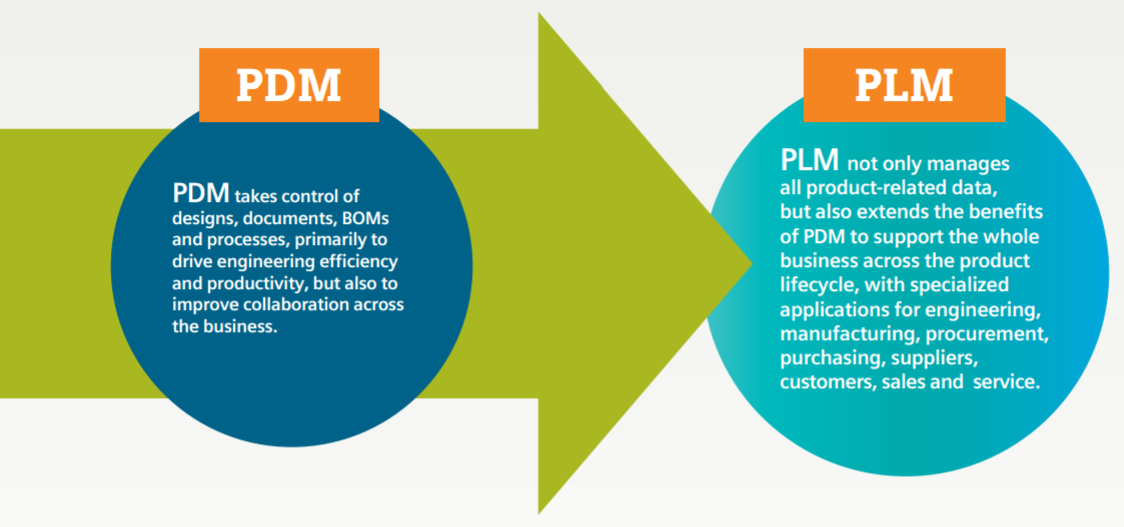

PLM can include data design and engineering change management, Requirements management, product design, purchasing, manufacturing production and packaging, supply chain management, product and process information management, integration of actual manufacturing and service data, supplier and partner management, service management, and the collection of data for lifecycle costing and benchmarking.

PLM can play an important role in different fields of engineering such as computer-aided design (CAD), computer-aided manufacturing (CAM), engineering simulation (ES), engineering analysis (EA), engineering recovery (ER), software engineering (SE), instructional technology, product family management (PFM), product costing and product marketing.