For older storage facilities, hydrocarbon spillages are a nightmare for tank terminal operators.

So, it is vital to have an immediate leak warning system at the site. This is the first sentinel before disaster escalation. In fact, the conclusion of a site assessment should include the installation of such systems.

Moreover, installing reliable and high-quality systems to detect hydrocarbons spillages and clean them using effective absorbents from ADsobit® could be the way to go.

Let’s have a look at the nuances of supervising various facility aspects using sensors for cost savings.

Supervising Treatment of Water

A monitoring sensor installed in the final retention tank can monitor the water quality and help to ensure the treatment process runs smoothly. Operators will be notified if there is an oil overflow at the exit chamber. The system can also automatically stop the discharge and contain oil to take the operator to take corrective actions.

Moreover, loading terminals that involve trucks containing refined oil to distribute oil to gas stations are always at risk of oil leaks and fire mishaps. To curb this, the terminal’s wastage can be drained to a sump, which collects both rainwater and potential oil spillages.

An oil sheen detector can also be installed in the sump to alert the operator when an oily substance is detected. The water will be filtered and treated to stop any further release.

Supervising Skimmers and Oil Tanks

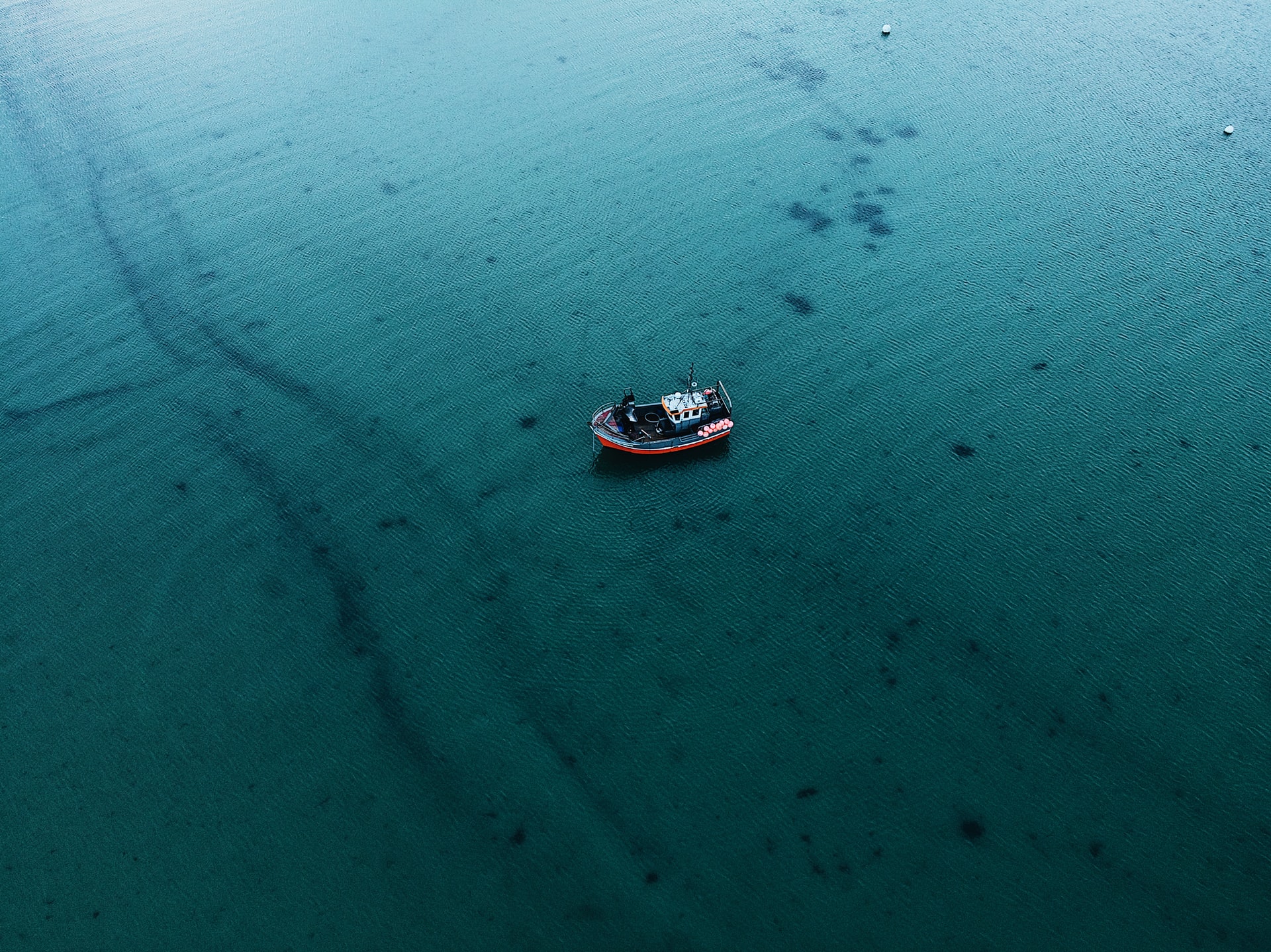

Water from the storage tanks can be collected and sent to an interceptor or separator where oil is separated. The water is then discharged to the ocean, river, or public water. An API separator could also be used to treat water from the tank.

A thickness monitor for oil can constantly monitor the thickness of the oil and notify the operator when it is time to skim. A control sensor can control oil skimmers automatically. It starts the skimming at a pre-set oil thickness and stops before any water is removed from the oil. This can lead to significant savings in disposal and treatment costs.

Supervising the Drainage Pipes

Rainwater that has accumulated on the roof of a storage tank can cause it to stagnate. So, it is necessary to drain it. You can do so by installing a flexible pipe that runs from the tank’s floating roof through the oil product and connects to the tank’s base.

However, there are many risks associated with this. The tank’s oil product can seep through flexible pipes through cracks or pinholes and then be drained through the drainage system without being noticed.

If the roof’s floatation is not balanced, oil products can flow over the roof through its seal and exit through the roof’s water drainage pipe. This can also happen during heavy rain or if the drainage pipe is partially blocked.

Note that local regulations might require that roof water be treated. You can reduce this by monitoring the drained water and diverting it to treatment if it contains oil traces. You need to know that overfilling of oil products could also occur during this process.

So, it is important to monitor the drain exits of each tank to inform management if there have been any leakages and what tank should be replaced. Any leakage can be detected by an oil sheen detector that is installed in a sump, retention tank, or local separator.

Supervising the Groundwater

Even the most sophisticated tank gauging systems can be unable to detect small leakages of oil or fuel from large tanks. According to current health standards, drinking water should not contain more than one ppm hydrocarbons. Undiscovered hydrocarbon leaks of more than one liter/gallon can cause groundwater contamination.

A groundwater monitoring well with an oil sheen detector can alert you about any hydrocarbon seepage in groundwater. This is more reliable than manual sampling.

A network of sensors installed in monitoring wells around a tank farm can detect leak drifting and layer thickness trends. Monitoring sensors can be placed in monitoring wells to detect if groundwater has been contaminated with oil. These sensors can measure the thickness of the oil layer up to 200mm.

We hope that the above tips were useful.