Printed circuit boards come in various forms. There are flex printed circuit boards, rigid-flex printed circuit boards, and rigid printed circuit boards. All are given their names based on their forms.

However, the three types of PCBs are different and are used in various devices. To help you understand more about them, here are the details between flex vs. rigid-flex vs. rigid PCBs.

What are PCBs?

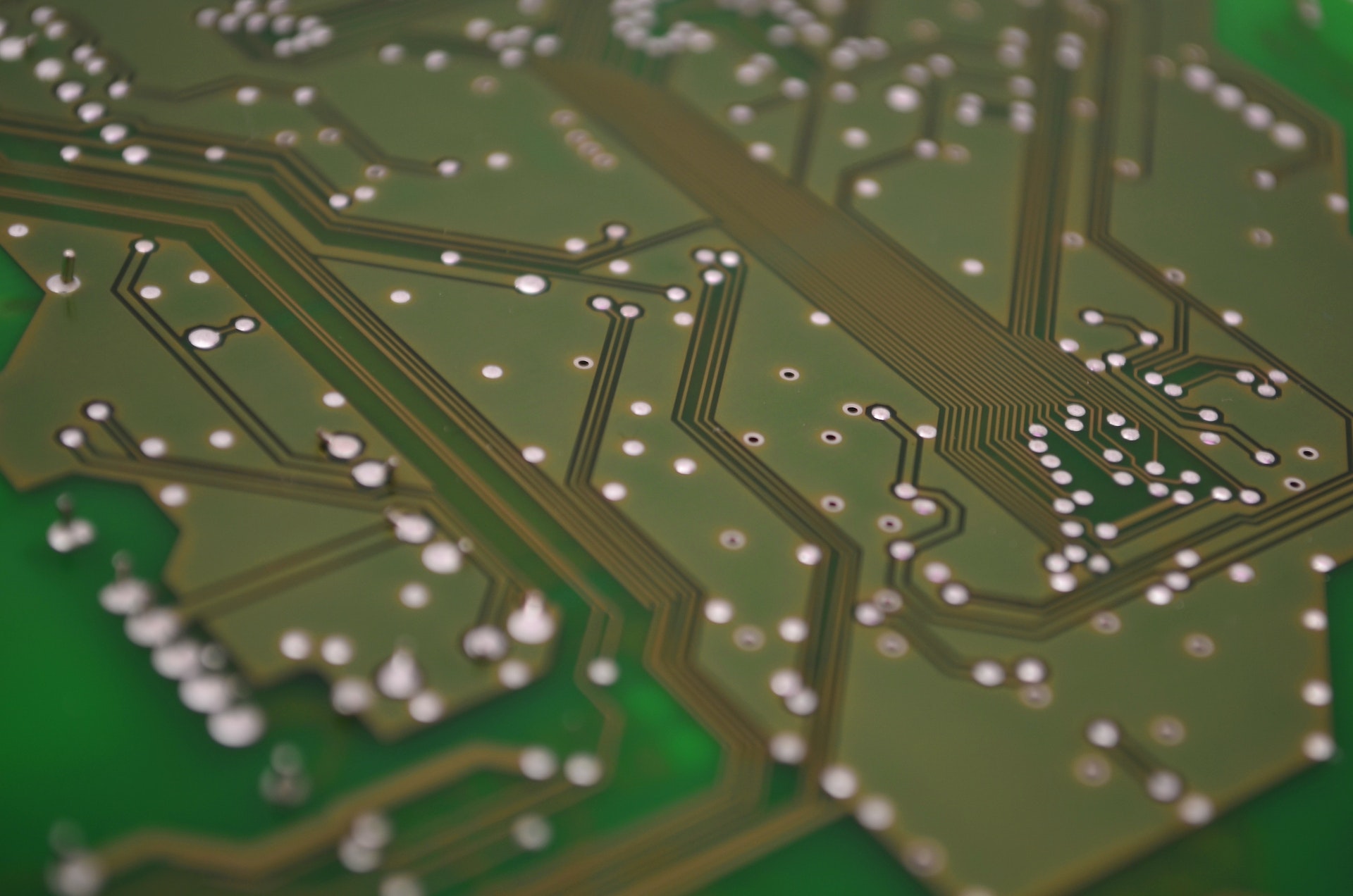

Printed circuit boards are vital elements responsible for the functionality of electronic devices. They help electronic gadgets to carry out pre-programmed commands. However, manufacturers can use flexible or rigid materials to make layers and components of a PCB.

The differences in material and design of the circuit boards impact the durability and efficiency of an electronic device. Moreover, some gadgets need flexible PCBs while others use rigid PCBs or rigid-flex PCBs.

The main types of PCBs based of how they are made are:

*Rigid PCB

*Flex PCB

*Rigid-flex PCB

What is a Rigid PCB?

Rigid PCBs are those that feature a solid, unbending board. They are popular among manufacturers because they are inexpensive compared to other boards. Also, they offer strength and durability since firm layers and materials are used to manufacture them.

Nevertheless, there are some drawbacks to rigid PCBs. First, their rigid nature makes it hard for them to fit into most electronics. Also, the thick and solid components contribute to the overall weight of the device, making them less portable.

Hence, even though rigid PCBs are preferred due to their strength and price, they can only be integrated into certain electronic devices. This is because of their thickness and weight.

What is a Flexible PCB?

Due to problems caused by rigid PCB material and design, an advanced circuit board was developed to provide flexibility. Flex printed circuit boards gained their name because they can connect many components despite being folded, bent, and creased into place.

Flex or flexible PCBs have a flexible base. And due to their ability to bend or fold into various shapes, flex PCBs have become popular in modern electronic devices.

Even though flexible PCBs come with numerous benefits, they are a bit more expensive than rigid circuit boards.

What is rigid-flex PCB?

Rigid-flex PCBs are created to have the advantages of both flex and rigid designs. It is a hybrid design that allows rigid-flex circuit boards to fit into particular requirements. Moreover, they are stable, sturdy, and dense.

Thus, the manufacturer of the PCB incorporates both rigid and flexible materials. This means these boards can easily bend and fit into their mechanical housing. This means rigid-flex PCBs can fit well into various electronic devices.

What is the difference between rigid PCB, flex PCB, and rigid-flex PCB?

Fabrication differences

Flex, rigid-flex, and rigid PCBs are fabricated differently. Different manufacturing methods are used to make the circuit boards. For instance, flexible circuit boards are made using an overlay process to ensure the components exposed to the circuit are protected.

On the other hand, rigid printed circuit boards are made using the normal green solder mask. Hence, there is a difference in how the PCBs are manufactured.

Differences in conductive material

Rigid, flex, and flex-rigid printed circuit boards are manufactured with different types of conductive materials. For example, rigid PCBs are manufactured from inflexible materials. For flexible PCBs, they are made from bendable annealed copper.

Differences in cost

A flex PCB is a bit expensive to make. This is because it is adaptable and is able to withstand many environmental factors than a rigid PCB. But since the PCB can be manipulated to fit even in smaller spaces, the entire size of the device can be reduced, saving a lot of costs.

On the other hand, rigid printed circuit boards are affordable in terms of cost and function in several electron devices. However, they are heavy and might not fit in smaller gadgets.

Differences in applications

Flexible printed circuit boards are unique and they allow PCB manufacturers to make a board that fits all the devices. But with rigid PCBs, the device needs to be made to fit the circuit board.

Flex PCBs are ideal for medical gadgets, drones, wearable electronics, and others. But rigid PCBs are perfect for vehicles and computers. This is because they cannot be folded.

Tips to consider when choosing PCBs

Rigid, flex, and rigid-flex PCBs find use in various products. However, some applications might benefit from more than one printed circuit board. For instance, rigid PCBs are ideal for larger products while flexible PCBs are perfect for compact products such as smartphones.

While choosing between flex, rigid, and rigid-flex PCBs, here are some tips to consider.

1. Application

The first and most important thing you need to consider is the application. You need to think of your application demands. If you are making large products such as computers, the best option is rigid PCB.

2. Cost

The other thing to consider is the cost of manufacturing the PCBs. You need to note that flex and rigid-flex PCBs are more expensive to build than rigid PCBs.

3. PCB supplier

It is also important to choose the right supplier. The fabrication process is a bit different between them. They need different equipment for the process, such as lamination, CNC machining, testing and so on.

Final Word

Printed circuit boards are elements that allow an electronic device to run and function correctly. But due to advancements in technology, the designs and materials of circuit boards have changed to accommodate modern devices.

Hence, there are rigid PCBs, flex PCBs, and rigid-flex PCBs. All three types of circuit boards are vital for making any kind of electronic. With the above information, you can be able to select the best type of circuit board for your product.